Yesterday Nanfang Daily reporter on the current pillar industry in Shenzhen, one of the electronic information industry in the intelligent production on the road farther and farther away this topic interviewed Shenzhen De Fu Lai Intelligent Technology Co., Ltd., and the company CEO Tu Guoquan conducted in-depth discussion The The next day, in the South Daily Daily made a special report on the map, the report reads as follows;

In Shenzhen City De Fu Lai Intelligent Technology Co., Ltd.'s exhibition hall, a large sand table shows the "smart factory" the whole picture. In this "unmanned factory", from the material entry, to the parts processing, parts assembly, quality testing, product packaging, warehousing logistics, can be assembled robots, intelligent visual inspection, automatic guide device (AGV) to complete. "In general, intelligent factories can reduce the cost of 20% for enterprises, the company's return on investment can be controlled in about two years." De Fu Lai CEO Tu Guquan said that the face of overcapacity pressure, the electronic information industry to reduce costs, Manpower, improve product quality has an urgent need, and thus become the main user of intelligent production program.

At present, the relevant units in Shenzhen are actively docking industry chain, so that smart manufacturing into the fast lane. However, Tu Guoquan that, although the industry has been the birth of a lot of industry 4.0 Union, but most of the lack of overall coordination, not yet mature. "Can not share the data, you can not really achieve intelligent manufacturing integration." A number of industry insiders believe that data isolation has become the biggest bottleneck.

According to the electronic information industry network announced on the 21st, China Electronics Information Industry Association issued 2017 China's electronic information industry innovation ability of the top 50 enterprises. Among them, Huawei Technologies Co., Ltd., ZTE Corporation, Skyworth Group Co., Ltd., Shenzhen Huaqiang Group Co., Ltd. and so on more than 10 Shenzhen enterprises on the list. The development of electronic information industry in Shenzhen can be described as the ever-changing. However, the challenges facing the industry bottlenecks, as one of the pillar industries in Shenzhen, how can the electronic information industry in the intelligent production on the road farther and farther?

Intelligent manufacturing has been "arrow on the string"

From the pursuit of speed to the pursuit of quality, which is the electronics industry in Shenzhen to adapt to the normal development of the industry. Shenzhen electronics industry is bid farewell to the amount to win, extensive business model, intelligent manufacturing has become the industry trend of development, for the enterprise can be described as "arrows had to send."

"Electronic information industry in recent years, the slowdown in growth, when the business collapse, indicating that the transformation and upgrading of the general trend." Nobuo Laser Intelligent Technology Research Institute, said Cao Feng, electronic information companies face many difficulties, not only the rapid increase in labor costs , Low profitability, low profits, and the user's demand for product consistency is getting higher and higher demand increasingly personalized and customization, which makes the intelligent manufacturing transformation of the urgent needs of enterprises.

To this end, the Shenzhen local business Hanjiao Laser Technology Industry Group Co., Ltd. in three years ago to enter the field of intelligent manufacturing for the 3C industry and new energy industry to provide production equipment unit, to achieve intelligent production and traceability.

Cao Feng told reporters: "We put the product core data uploaded to the customer's server, in the production process, each station has a bar code gun record product production date, batch, supplier, test results, the system automatically upload these information To the MES system. When a product is abnormal, the system can be accurately traced back to the date and batch of the product, combined with the background data analysis may be in which part of the problem.

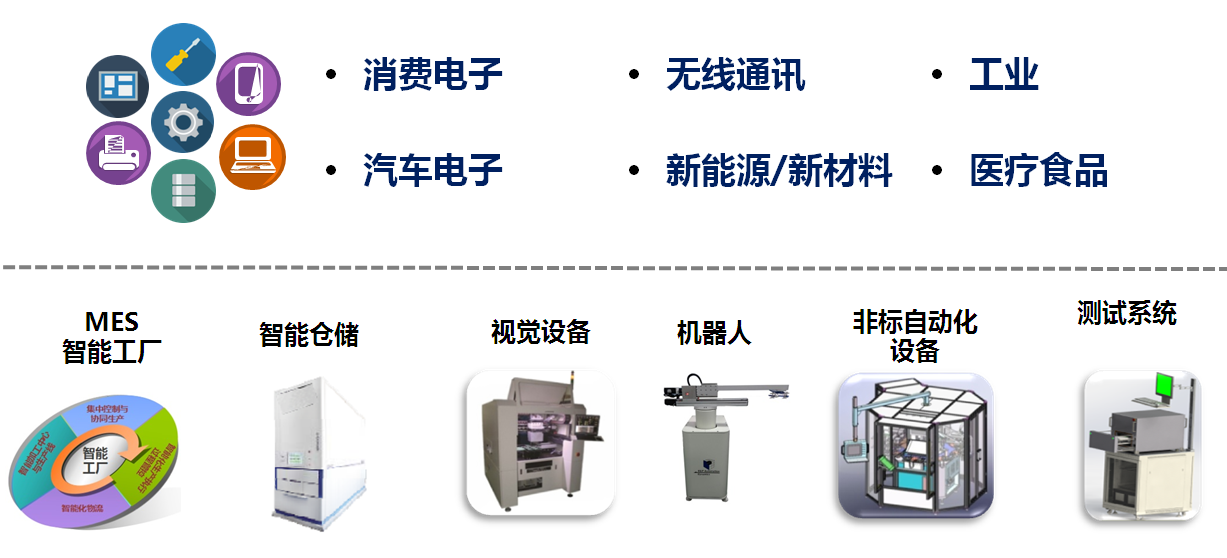

In addition to intelligent production equipment unit, Shenzhen De Fu Lai Intelligent Technology Co., Ltd. has been the first in the industry to achieve a smart plant hardware and software one-stop solution, the entire intelligent factories, including intelligent warehouses, MES systems, visual equipment, non-standard automation , Test systems and robots. In cooperation with Apple, Microsoft, Huawei, ZTE, BYD, Lenovo, Foxconn and other enterprises in the process of cooperation, Defoe according to the customer's actual situation, tailored for now and long-term development of intelligent factory solutions.

"Shenzhen electronic information industry has a huge demand for intelligent manufacturing solutions market demand, and the vagaries of the demand environment." De Fu Lai CEO Tu Guoquan stressed that at present, Shenzhen intelligent manufacturing enterprises need to strengthen the integration of the program to provide capacity for Market advantage into industrial advantages to provide the starting point.

"There is still distance from the real intelligence"

In fact, in the enterprise to promote the intelligent manufacturing process is not smooth sailing, Shenzhen Penbo Technology Co., Ltd. had to "pay the tuition", also received valuable experience.

To replace the pure hand production, the company from 2008 to 2010 the implementation of non-standardized automation projects, and later found not only can not reduce costs but will cause waste. Pennefather Technology Robot Division responsible person told reporters that the keyboard and mouse products in various forms, update iteration fast. "If we have a set of non-standardized system equipment for each form of product, once the market demand changes, these system equipment will no longer be used, into scrap. And non-standardized custom equipment quality and accuracy are not long-term Long-term industrial robots, and the system into a standardized, greatly improving the equipment reuse rate. "So far from the beginning of 2010, Pennefather technology companies to order high-end industrial robots, and the system into a standardized, greatly improving the equipment reuse rate.

On the direction of the development of intelligent manufacturing, Cao Feng said: "We understand the intelligent manufacturing should be, when the electronic product iteration, process changes, no need to do more product validation, there will be a set of product standard parameters.As long as the order, It can be pushed to the manufacturer ERP system, the system based on data production to develop products, and then through the logistics business will be shipped back, so very intelligent.

At the same time, Cao Feng also saw the current manufacturers are mostly introduced only part of the equipment and production processes, equipment manufacturers to develop their own different parameters of the equipment, from the real intelligent, standardized production there is a certain distance. With the German De Fu Lai CEO Tu Guquan words, "automated production nearly 5-8 years to achieve, China made 2025 nearly two years has just started.We are running on the road, hardware to hardware, software software, not connected together

At present, the relevant units in Shenzhen are actively docking industry chain, so that smart manufacturing into the fast lane. However, Tu Guoquan see the situation shows that although the industry has been the birth of a lot of industry 4.0 Union, but most of the lack of overall coordination, not yet mature. "The company 's core things have reservations, no one wants to share some of the benefits in this piece of cake, can not share data, you can not really achieve intelligent manufacturing integration.

"For the industry to build standards, is the first-class company"

Many experts and the industry believe that data isolation is the realization of intelligent all-industry chain production of the biggest bottlenecks. Cao Feng said that each device manufacturers have their own independent data format, the factory, between the software, between hardware and hardware and software between the data barrier. From the automation point of view, the data can not be achieved through the industrial interconnection, intelligent factories can not be established.

"In the case of data unreasonable, the industrial structure is irrational, and thus there have been a lot of excess capacity." Guangzhou Wise Cloud Technology Co., Ltd. Vice President Xing Yan said that the production planning problem is the traditional manufacturing industry is facing the largest and even the most fundamental The problem, when the problem is resolved, intelligent factory will be basically able to complete.

In order to break through the data barriers as soon as possible, Han's laser plan to small businesses as a breakthrough to collect data, these small and medium enterprises are large manufacturers supporting manufacturers. Cao Feng said, Han's laser will use two to three years for small and medium enterprises to establish a complete set of intelligent production system to provide low prices, while collecting these business data, in order to get through the industry chain last ring to promote the entire industry chain Sales. "We have long been in contact with Foxconn, has collected a lot of information, small customers and large customers in the information communication level to achieve the same.

Open up the data barriers, standardization has a foundation. At present, a number of responsible industry leading enterprises are actively working together to design a unified intelligent production of the overall solution. Cao Feng told reporters: "Because of the design from the design to the confidentiality of the parameters, large customers are doing their own MIS system, in the absence of industry standards of chaos. Han's laser, Kingdee and other hardware and software vendors are planning to cooperate, A complete set of production equipment and systems. "

"Third-tier enterprises to do accessories, second-rate enterprises to do products, first-class enterprises to do the standard." In the Chinese Academy of Engineering Tan Jianrong view, such as Shenzhen Foxconn such large enterprises in the forefront of technology, but the face of the future situation, still can not be called As "first class company". He proposed to build standards for the industry in order to represent the advanced nature of the enterprise in order to grasp the industry's right to speak.

Copyright © B&P Automation Dynamics Ltd.